EPOCH 6LT

.

.

The EPOCH 6LT Portable Flaw Detector

Elevate Your Inspections

Don’t compromise on the inspection capabilities of your flaw detector. The EPOCH® 6LT portable flaw detector combines the functionality of a powerful ultrasonic flaw detection device with a form factor designed to thrive in rope access and high portability applications.

Reliable Flaw Detection in the Palm of your Hand

Portable and easy to use, the EPOCH 6LT flaw detector is an ergonomic, rugged instrument that delivers user comfort and more uptime.

- Weighs just 1.95 pounds (890 g) with a grip-oriented weight distribution for one-handed operation with minimal wrist fatigue

- Rotary knob and simple button design make it easy to use, even when wearing gloves

- Engineered to IP65/67 and drop tested

- Clear, bright screen for readable A-scans in any light

More Functionality on the Go

The EPOCH 6LT flaw detector’s workflow is simple and straightforward. Despite the instrument’s small size, it has the features and functions to meet the requirements of nearly any conventional ultrasonic inspection application.

- Offers all the core functionality of the EPOCH 650 flaw detector in a small, portable instrument

- Meets the requirements of EN12668-1:2010

- Optional corrosion software with center-pin transducer ID

- Optional Wireless LAN connectivity

Designed for Rope Access and Ultra-High Portability Applications

For rope access technicians, the EPOCH 6LT flaw detector offers features to help keep you safe during challenging inspections.

- With the optional rope access accessory kit, secure the instrument to your leg with a strap or attach it to your harness, leaving your hands free to maintain balance or adjust the probe

- Rotate the display from portrait to landscape to properly view the A-scan and readings

- For greater flexibility, the 1/4-20 threaded insert enables you to connect the flaw detector to a wide variety of Olympus and third-party accessories

SOFTWARE FEATURES

Powerful Features Optimized for One-Handed Operation

The EPOCH® 6LT portable flaw detector has a variety of standard and optional software features designed to meet a wide range of flaw detection applications.

Exporting saved inspection files for reporting is easy. Send your inspection results to a removable USB memory stick in a variety of convenient file formats, such as BMP, CSV, and PDF, to quickly communicate your data.

Connected and Cloud Enabled

With optional Wireless LAN, connect your flaw detector to the Olympus Scientific Cloud and access powerful cloud-based features, including:

- Wireless firmware upgrade

- File backup and archiving

- Remote file access and management

Cloud file management includes all EPOCH 6LT file types, making it easier than ever to report and communicate your inspection results.

Learn more about the Olympus Scientific Cloud

Standard Software Features for Reliable Flaw Sizing

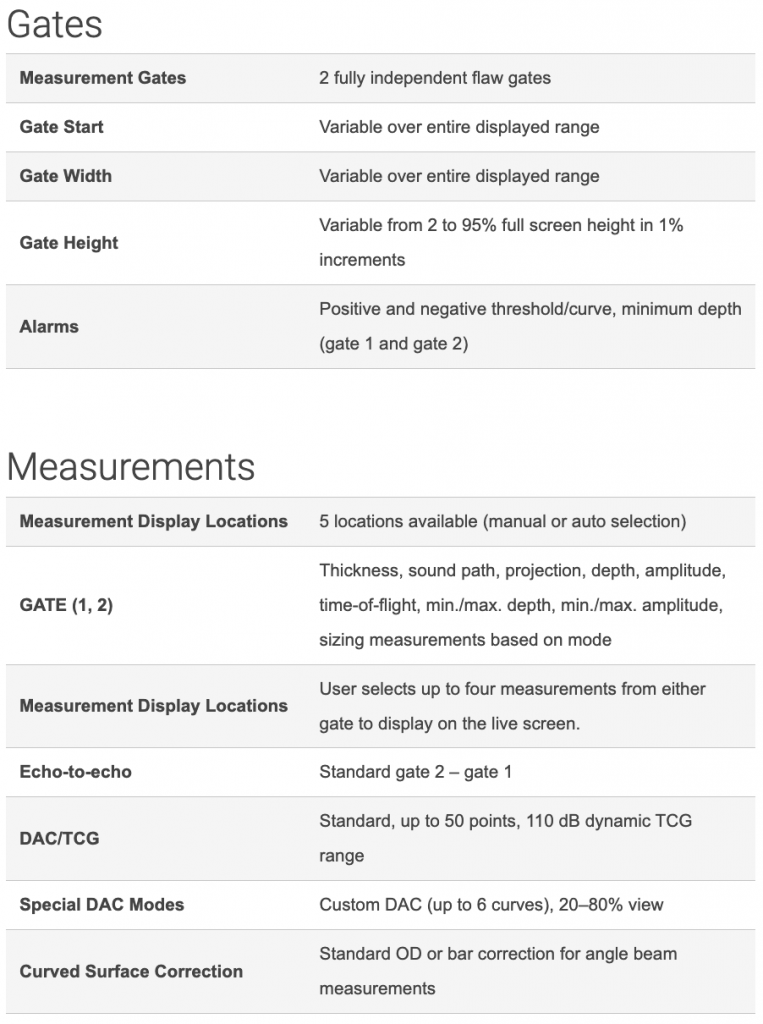

Dynamic DAC/TCG: Calculates signal amplitude as a percentage or decibel level compared to a DAC curve or a reference echo amplitude fixed at a time-varied gain. The DAC version includes standard, custom DAC warning curves, and 20–80% views.

DGS/AVG: Enables echo signals to be evaluated with a DGS/AVG diagram, which illustrates the relationship between echo height, flaw size, and distance from the transducer.

AWS D1.1 and D1.5: Provides a dynamic reflector indication rating for various AWS weld inspection applications. This enables more efficient inspections by eliminating manual calculations.

Added Versatility: Optional Software Features

Corrosion Module: For corrosion inspections, this feature enables automatic ultrasonic setups based on transducer selection with automatic probe recognition for all standard Olympus corrosion dual transducers, Automatic Gain Control (AGC), a thickness gage measurement algorithm, true V-path correction, and transducer wear compensation using an automatic zero function (“Do Zero”). The module also features a color-coded grid view for improved corrosion reporting capabilities.

Back Wall Echo Attenuator (BEA): Attenuates the back wall of an inspected part using the screen region defined by Gate 2. BEA software enables the user to monitor for back wall drop off while scanning at a high gain level.

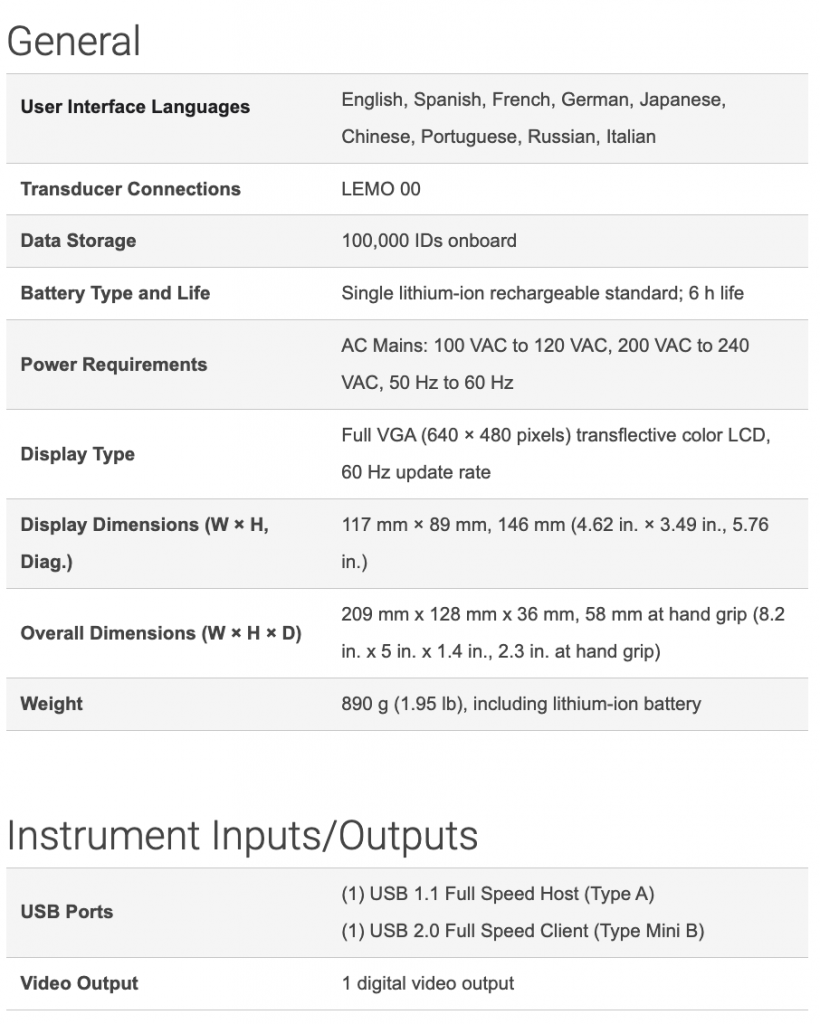

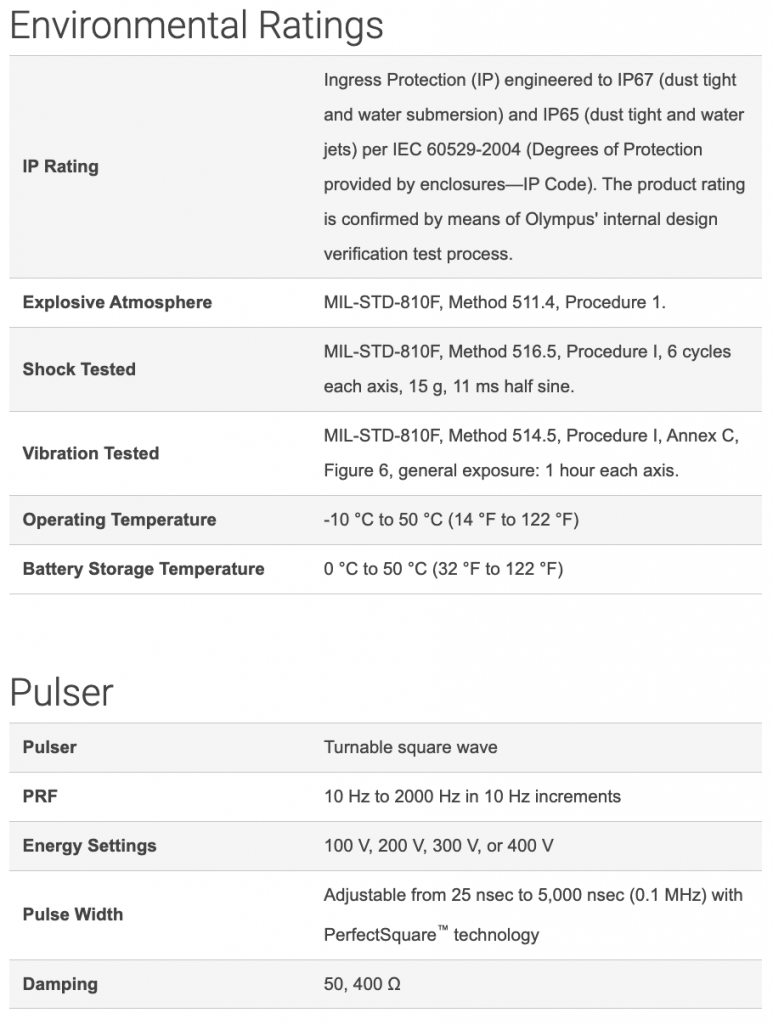

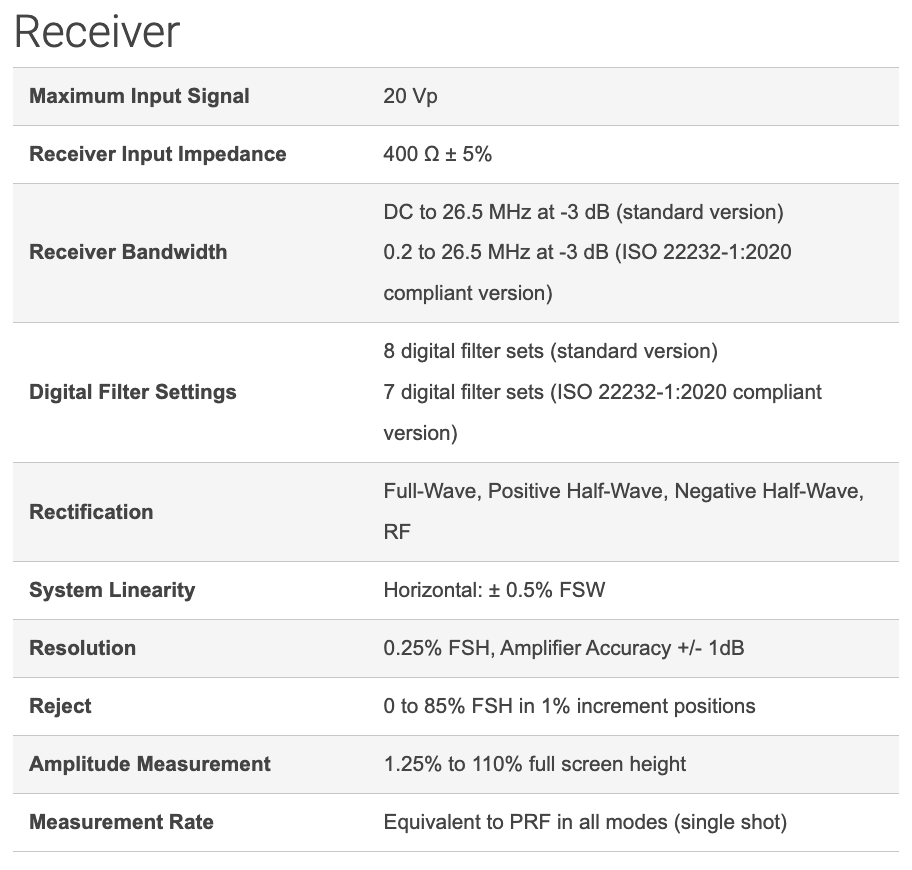

Specifications