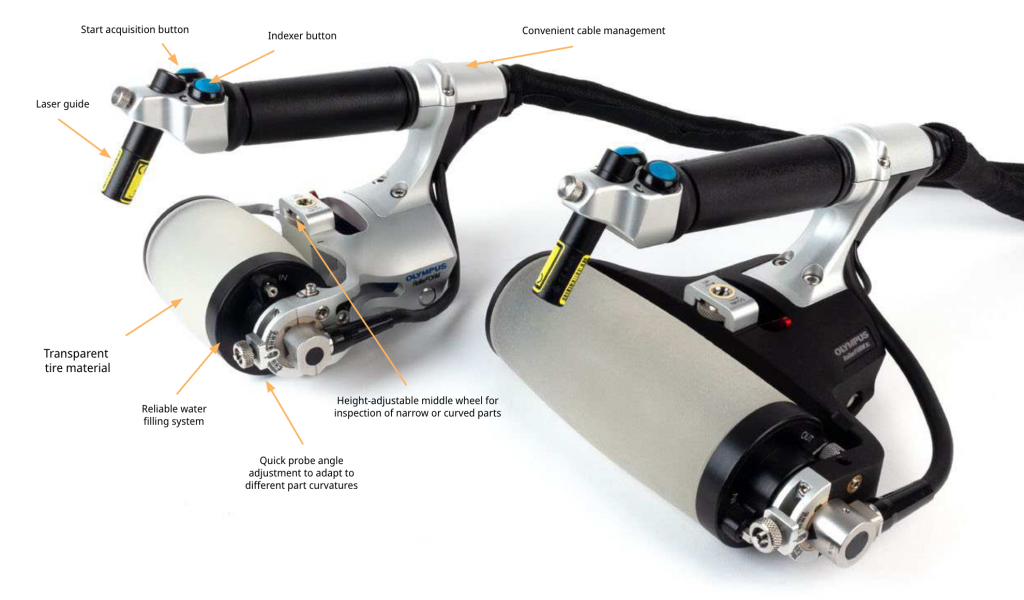

RollerFORM

Phased Array Wheel Probe

C-Scan Inspection without Immersion

The RollerFORM™ phased array wheel probe is used to inspect composites and other smooth-surfaced materials. An affordable and easy-to-implement replacement for full 2D encoding systems, the RollerFORM scanner is a viable alternative to immersion techniques.

The RollerFORM tire’s unique material provides high-quality, immersion-like ultrasonic testing. Minimal couplant and pressure are required to achieve excellent coupling and a strong signal, even in difficult scanning positions.

Features

- Offered in two sizes with a 51.2 mm or 128 mm beam width.

- Exceptional coupling with minimal couplant.

- Acoustic impedance similar to water.

- 25 mm water delay line enables inspection of composites up to 50 mm thick.

- Can be used in accordance with existing aircraft manufacturer procedures.

Standard Inclusions

- Phased array probe with OmniScan connector.

- Waterproof encoder.

- Laser guide.

- Indexer and Start Acquisition buttons.

- Filling/spraying pump and tubing.

Just Roll It for Instant Results

The RollerFORM scanner, combined with an OmniScan flaw detector, uses zero-degree ultrasonic beams for manufacturing and maintenance inspections. Common applications include delamination sizing and porosity quantification in composite core material, as well as wall-loss monitoring in metals.

The RollerFORM XL scanner’s wider tire and probe offer greater coverage for increased productivity and improved probability of detection (POD). For more attenuative materials, the 1 MHz version of the RollerFORM XL scanner has a larger aperture, which improves the ultrasound beam penetration for challenging applications such as wind blade spar cap and shear web bonding.

Ergonomically designed scanner

- Integrated indexing button enables you to map inspected surfaces by acquiring multiple one-line C-scans and combining them in real time into a single image

- Built-in laser guide facilitates straight, precise one-line scans

Advanced tire

- Exceptional coupling

- Tire’s unique material closely matches the acoustic impedance of water, enabling efficient transmission of ultrasound energy to the part

- Transparent tire makes it easier to spot air bubbles or contaminants in the water chamber

Frequently Asked Questions

Can the RollerFORM scanner be used for applications other than aerospace or wind blade inspection?

The RollerFORM design is optimized for inspecting for defects in the volume of composite materials that are 2 to 50 mm thick as well as disbonding between layers. However, the RollerFORM scanner can also be advantageous for other applications, though it’s important to keep in mind that the maximum frequency available is 5 MHz and the maximum allowable surface temperature is 80 °C, or 176 °F (maximum 2 minutes continuous inspection time). To discuss other applications, please contact your local Olympus representative.

Can the RollerFORM inspect honeycomb panels?

The RollerFORM scanner can detect defects in the volume of CFRP skin that is 2 to 50 mm thick. It can also be used for near-side detection of disbonding between CFRP layers (thicker than 2 mm) and honeycomb structures for certain material combinations. However, the BondMaster bond tester remains the recommended method for disbond detection between CFRP and honeycomb and for delamination detection in CFRP layers thinner than 2 mm.

Can the RollerFORM be used for corrosion mapping inspection?

Yes. Even though the HydroFORM scanner remains the ideal choice for corrosion inspection, the RollerFORM scanner is a suitable option for corrosion applications that do not require optimum near-surface resolution (NSR) or high frequencies. Furthermore, the RollerFORM scanner can be particularly useful for quick checkups or when performing strip inspections on the longitudinal axis of pipes that are 4 in. OD or greater. The RollerFORM scanner has a 3 mm NSR in steel (as opposed to 1.5 mm for the HydroFORM) and has a maximum frequency of 5 MHz. The HydroFORM is also better suited for integration with full 2-D mapping scanners.