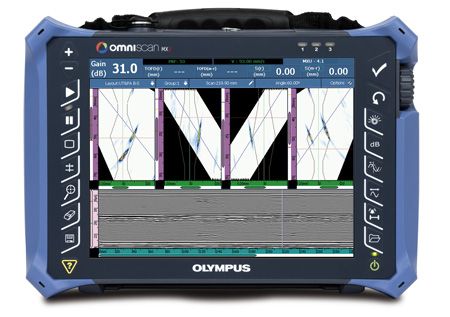

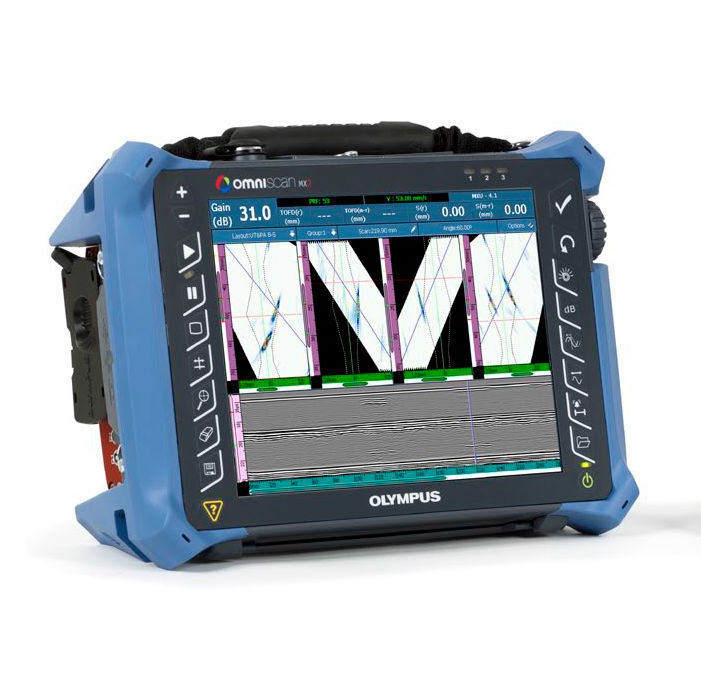

OmniScan MX2

Thickness and Flaw Inspection Solutions

The result of over 10 years of proven leadership in modular NDT test platforms, the OmniScan MX has been the most successful portable and modular phased array test instrument produced by Olympus to date, with thousands of units in use throughout the world. Olympus now offers a new PA module with TOFD, a new UT module, as well as new software programs (NDT SetupBuilder and new OmniPC version) that expand the capabilities of the successful OmniScan MX2 platform and improve the workflow efficiency of nondestructive testing inspections.

This second generation OmniScan MX2 increases testing efficiency, ensuring superior, advanced AUT application performance with faster setups, test cycles, and reporting, in addition to universal compatibility with more than 10 phased array and ultrasound modules. The OmniScan MX2 offers a high acquisition rate and new powerful software features for efficient manual and automated inspection performance—all in a portable, modular instrument.

Faster Is Better!

Powerstart your day with the OmniScan MX2. The OmniScan MX2 simplifies and speeds up the setup process with its intuitive step-by-step Wizard, so you can start testing quickly. Featuring the industry-standard phased array user interface with faster-than-ever performance, a bigger and brighter 10.4 in. (26.4 cm) screen, new and unique intuitive touch-screen capabilities, and faster data transfer, the MX2 enables you to get to your next inspection quicker.

More than an Instrument-A Solution Provider

The OmniScan MX2 is an important part of your inspection solution, and can be combined with other critical components to form a complete inspection system. Olympus offers a complete product range that includes phased array probes, scanners, analysis software, and accessories, all of which are integrated and packaged into rapidly deployable, application-specific solutions for a quick return on your investment. In addition, Olympus offers a high-quality global calibration and repair service, backed by a team of phased array application experts to ensure that you get the support you need.

More than an Instrument-A Solution Provider

The OmniScan MX2 is an important part of your inspection solution, and can be combined with other critical components to form a complete inspection system. Olympus offers a complete product range that includes phased array probes, scanners, analysis software, and accessories, all of which are integrated and packaged into rapidly deployable, application-specific solutions for a quick return on your investment. In addition, Olympus offers a high-quality global calibration and repair service, backed by a team of phased array application experts to ensure that you get the support you need.

Pressure Vessel Weld Inspection

Composite Inspection

.

Olympus offers complete solutions for the inspection of carbon-fiber-reinforced polymer structures. These solutions are based on the OmniScan flaw detector, the GLIDER™ scanner, and dedicated probes and wedges designed for CFRP flat panel and radius inspection.

Weld Inspection of Small-Diameter Pipes

Manual and Semiautomated Corrosion Mapping

For this application, phased array ultrasound technology offers superior inspection speed, data point density, and detection.

Modular Instrument

A Platform that Evolves as your Needs Grow

Designed to secure both your current and future phased array investments, the OmniScan MX2 houses more than 10 different Olympus modules. You can be confident that you will get the most out of your investment as specifications will continue to evolve with your needs through constant software updates.

State of the Art PA2 and UT2 Modules

As a world leader in phased array technology, Olympus has released a new line of modules compatible with MX2 instrument.

16:128 PA2

32:128 PA2

32:128PR PA2

PA2

The new phased array offer-led by the new innovative PA2 modules, features multiple improvements, such as:

Best Phased Array and TOFD Signal Quality Ever

- Better signal-to-noise ratio

- More powerful pulsers

- 64 pure gray tone

More Multi-group Capabilities

- Ability to use PA and UT channels simultaneously

General Hardware Improvements

- Higher operating temperatures (45 °C)

- New OmniScan probe connector with quick latch system

- Designed for IP66 environmental rating

- Extended autonomy on batteries

UT2

The new conventional ultrasound module features the same UT-channel technology as the PA2 modules, but offers twice as many channels.